Most Popular Products

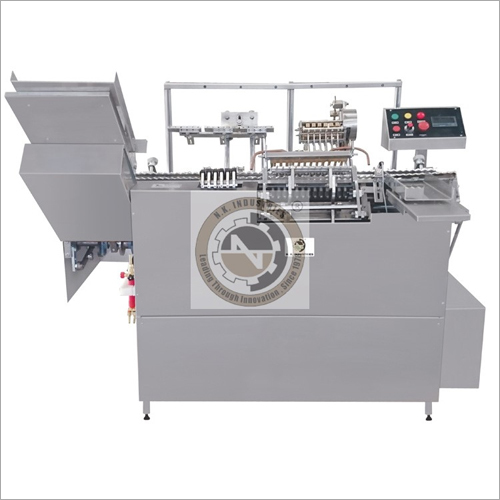

Single Head ROPP Capping Machine

Product Details:

X

Product Description

Salient Feature of Machines

- Parts coming in contact with the vial / aluminum cap / exposed to the atmosphere are made out of stainless steel, good housekeeping and good manufacturing practice.

- Single motor synchronizes conveyor, star wheels and platform turret and speed can be varied by the % speed pot on operating panel.

- A Special clutch device is incorporated on the in feed worm and Star wheel system for stoppage of machine in the event, vial is over turned or over diameter.

- A photo sensing device stops machine automatically in the event, there is no aluminum cap in delivery chute.

- Sealing Pressure can be varied to suit different gauges and sizes of ROPP caps.

- Damage cap quantity can be reduced by adjusting the gap between upper and lower plate of orientation unit.

- Imported Gear Motor for Main drive.

- Imported Gear box for Orientation unit.

- Allen bradly make A.C. Frequency drives for Main drive.

- Digital Counter for counting number of sealed BOTTLE.

- No Seal in Chute, Machine Stops System

- NKCS-60R Automatic Single Head ROPP Capping Machine is a compact model used for sealing of ROPP Cap on the bottle.

- Previously filled bottles with Dry Syrup Powder or Liquid Syrup are continuously fed from filling machine to the flat conveyor belt of sealing machine and move further through in feed worm for correct spacing between two bottles and transferred to the in feed star wheel.

- ROPP caps kept in orientation unit automatically orient caps in right direction before entering into delivery chute.

- And Bottle is entering below the sealing head, consist of total four rollers. Two rollers properly Skirts, Spins and Seals the cap and simultaneously another two roller performs perfect threading according to bottle neck diameter.

- After sealing operation, sealing head moves upward with help of cam and bottle move with exit star wheel and Move further on conveyor belt for next operation.

Technical Specification:

| Single Head ROPP Capping Machine | |

| Direction | Left To Right. |

| Production Rate | Up to 35 To 60 Bottles / Min |

| Electrical Supply | 1.00 HP For Main Drive |

| No of Sealing Head | Single |

| Power Requirement | 440 Volts, 3 Phase (4 wire System) 50 Hz. |

| Height of Conveyor | Adjustable from 800 To 850 MM |

| Dimensions | 1600 MM (L) X 750 MM (W) X 1900 MM (H) |

| Net Weight | 550 KGS (Approx.) |

| Gross Weight | 740 KGS (Approx.) |

| Bottle Diameter | 22 MM To 65 MM MAX. |

| Height | 55 MM To 110 MM MAXIMUM. |

| ROPP Caps | 22, 25 & 38 MM DIAMETER.(with help of change parts) |

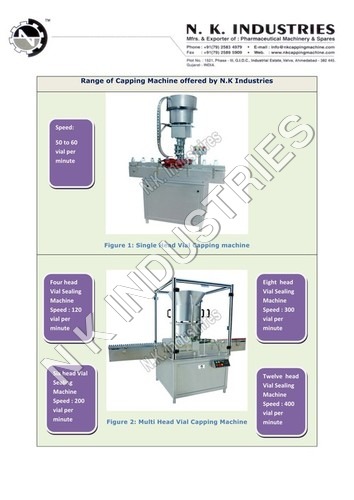

Other Products in 'Capping Machine' category

|

N K INDUSTRIES

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese