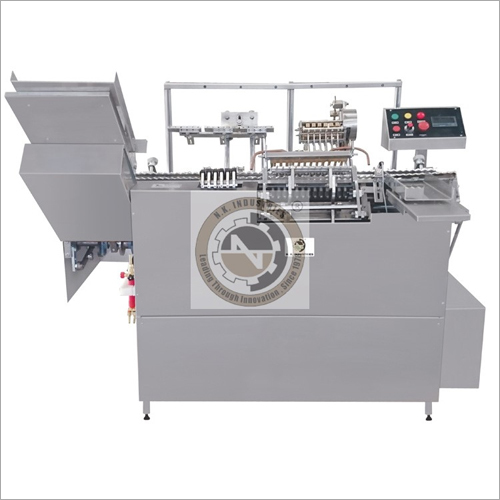

Semi Automatic Dry Powder Filling Machine

Product Details:

Product Description

Abiding by our clear policies and dedicated team of experts we are engaged in offering our precious clients seamless Semi Automatic Dry Powder Filling Machine. It is made in adherence with the international quality standards and norms using latest machines and exceptional quality components. As a result, Semi Automatic Dry Powder Filling Machine provided by us is hugely in various industries for filling powder. Due to all, we are reckoned as market centric manufacturer, exporter and supplier.

Salient Feature:

Semi Automatic Dry Powder filling machine is equipped with following features:

- A CGMP Model.

- "NO VIAL, NO FILL System eliminates wastage of costly powder.

- Works on combination of Vacuum pressure dosing system which in turn reduces residual powder at the end of the batch to a minimum.

- Facility of Simultaneous adjustment of dosing port volume.

- Simple, fast & repeatable changeover.

- Positive vial transport i.e. star wheels guide the vials through the filling, stoppering stations, ensuring they remain upright and guaranteeing correct placement.

- All contact parts i.e. Parts come in contact with powder are made of SS316 material with easy removal system for Autoclaving / Sterilization.

- Hopper can be completely dismantles for easy cleaning

- Multiple dosing of injectable powder or changeover of container size and different fill size is possible by just changing the vial separator or size of the piston respectively.

- Special clutch devices are provided on vial separator for safety purpose.

- Vacuum filter will be of PVC transparent material with nylon cartage having length of 10.

- No Stopper in Chute, Machine Stop System.

Technical Specification :

| Filling Speed | 40 Vials/minute based on 5-10ml vial for Single Dosage |

| Design | Left to Right |

| Dosage | 50 mg to 1.5 grams. Single Dose (with Change Parts) |

| Dosing wheel | One |

| Dosing port / Wheel | 8 Nos |

| Via Diameter | 25 mm to 45 mm max |

| Vial Height | 75 mm maximum |

| Power Supply | 0.5 HP , 230V, 1 phase |

| Fill Accuracy | 2% depending upon consistency and uniformity of bulk density of injectable powder |

| Bottle Loading | On provided bottle Platform |

| Powder Suction | Through Vacuum |

| Powder Delivered | Through Air/Nitrogen (Customer to Provide) |

| Machine Dimension | 525 (mm) X 600 (mm) X 650 (mm) |

Other Products in 'Injectable Dry Powder Filling Machine' category

|

N K INDUSTRIES

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese