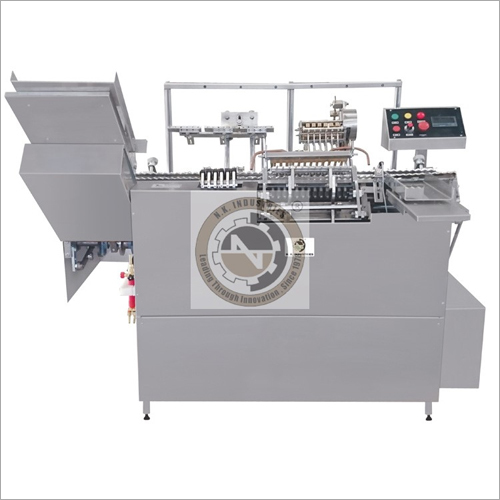

Monoblock Dry Syrup Powder filling Machine

Product Details:

Product Description

Having immense market shares, we fulfill the wide requirements of our patrons by providing top quality Monoblock Dry Syrup Powder filling Machine. The provided machine is manufactured using optimum quality components as per industry standards with the aid of ultra-modern techniques by our ingenious professionals. This machine is widely used in pharmaceutical, chemical and cosmetic industry for filling dry syrup powder. Apart from this, our clients can avail the offered Monoblock Dry Syrup Powder filling Machine at most competitive prices from us.

Key Points:

- High load bearing capacity

- Longer working life

- Less maintenance

- Smooth finish

Salient Features:

- High Production Capacity in High Filling Quantity also.

- M.S. Molded structure duly powder coated to avoid any vibration with adjustable Screws to adjust conveyor height as per in feed tunnel.

- Total Compact Monoblock CGMP model.

- All parts and assemblies coming in contact with powder are made of S.S.316

- "NO BOTTLE, NO FILL" System eliminates wastage of costly powder.

- Spring loaded top seal for powder hopper reduces the friction between and top seal and avoid chance of white particle shading during production.

- Doctor blade and wiper blade can be adjusted from outside also without disturbing any production, which saves lot of time, powder wastage and chances of area condition disturbance.

- All assemblies under top plate are positioned as for easy cleaning or maintenance.

- All driving is through High quality imported Gear motor.

- Machine speed can be adjusted through A.C. Frequency drive, which is time saving.

- Machine is provided with Delrina conveyor belt to avoid sticking of bottle on conveyor.

- Special clutch devices are provided on Star wheels for safety purpose.

- Air filter will be of S.S.316 housing with Nylon cartridge for proper removal of particle of 0.22 micron having 10" length.

- Vacuum filter will be of PVC transparent material with nylon cartridge having length of 10" of 5 micron.

- Machine can fill 10 grams to 50 grams powder in single stroke.

|

MODEL NO. NKPF-MR150 |

|

|

Direction |

Left To Right. |

|

Production Rate |

Up to 100 to 120 Bottles / Min. |

|

Fill Capacity |

10 grms to 50 grms. Single Dose (with change parts) Fill range depending upon Bottle opening And bulk density of powder. |

|

Accuracy |

± 2% depending upon consistency and the Uniformity of bulk density of powder Under controlled level of Humidity (i.e.35%) |

|

Electrical Supply |

2.00 HP For Main Drive. |

|

Power Requirement |

440 Volts, 3 Phase (4 wire System) 50 Hz. |

|

Height of Conveyor |

Adjustable from 900 To 950 MM. |

|

Dimensions |

2400 MM (L) X 1506 MM (W) X 2163 MM (H) |

|

Net Weight |

1700 KGS. (Approx.) |

|

Gross Weight |

2200 KGS. (Approx.) |

|

Bottle Diameter |

25 MM To 60 MM MAX. |

|

Height |

55 MM To 110 MM. |

|

Pneumatic Air |

Filtered, oil free, sterile low pressure AIR at 4 kg/cm2 (4/6 bar) |

|

Vacuum line |

20 HG. (Pump will be supplied by N.K.) |

|

N K INDUSTRIES

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese