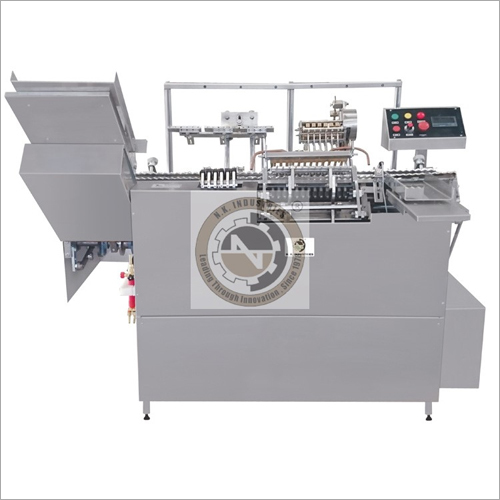

Injectable Dry Powder Filling Machine

Product Details:

Product Description

Key Points:

- Maintenance free

- High performance

- Fine finish

- Rust resistance body

Salient Features

- Compact footprint

- CGMP Design.

- Highly precise powder dosing system based on Vacuum -pressure.

- Simple, fast and repeatable changeover.

- Positive vial transport system i.e. vial separator guide vials through module like filling, stoppering ensuring they remain upright during transport.

- Parts come in Contact with Sterile Powder & Rubber stoppers are of AISI 316L.

- Multiple dosing of injectable / sterile powder or changeover of container size and different fill size is possible by just changing the vial separator or size of the piston respectively

- "NO VIAL NO FILL"Â scheme eliminates wastage of costly Powder.

- Special delrin conveyor belt to avoid sticking of vial on conveyor.

- All electronics are of CE Certified.

- Vacuum Filter of 10 micron and Air filter of 2 micron.

- The electrical system of the equipment is being housed as per cGMP and cGEP standards with adequate safety

- Digital Vacuum and pressure switch for monitoring vacuum and Air.

Technical Specification:

|

Machine Name |

Automatic single head injectable dry powder filling machine |

Automatic Double head injectable dry powder filling machine |

|

Model |

NKPF-120 |

NKPF-240 |

|

Filling Speed |

120 Vials/minute based on 5-10ml vial for Single Dosage |

240 Vials/minute based on 5-10ml vial for Single Dosage |

|

Design |

Left to Right |

Left to Right |

|

Dosage |

50 mg to 1.5 grams. Single Dose (with Change Parts) |

50 mg to 1.5 grams. Single Dose (with Change Parts) |

|

Dosing wheel |

One |

Two |

|

Dosing port / Wheel |

8 Nos |

8 Nos |

|

Fill Accuracy |

±2% depending upon consistency and uniformity of bulk density of injectable powder |

±2% depending upon consistency and uniformity of bulk density of injectable powder |

|

Product Conveyor |

50 mm (2") wide delrin conveyor |

50 mm (2") wide delrin conveyor |

|

Powder Suction |

Through Vacuum |

Through Vacuum |

|

Powder Delivered |

Through Air/Nitrogen (Customer to Provide) |

Through Air/Nitrogen (Customer to Provide) |

|

Stopper Delivered |

Through Vibratory Bowl & Chute |

Through Vibratory Bowl & Chute |

|

Machine Dimension |

1830 (mm) X 915 (mm) X 1600 (mm) |

2100 (L) x 1170 (W) X 1600 (H) |

Other Products in 'Injectable Dry Powder Filling Machine' category

|

N K INDUSTRIES

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese