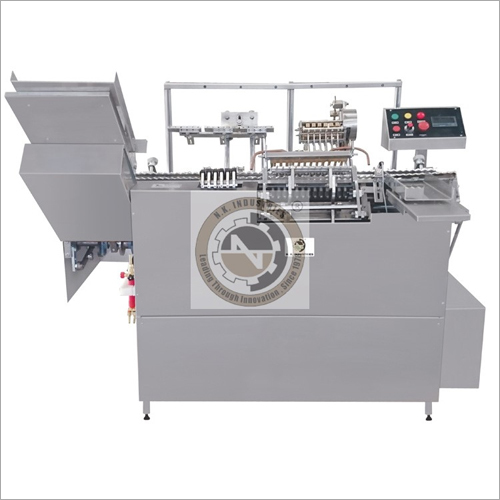

Bottle Capping Machine

Product Details:

Product Description

Being a client centric entity, we are counted among the renowned organization of premium grade Bottle Capping Machine. This machine is widely used in for bottle capping, perfume bottle sealing, cap sealing, metal sealing, wine sealing capping etc. The offered machine is manufactured with the use of premium quality components and highly advanced techniques. Additionally, our clients can purchase the provided Bottle Capping Machine at market leading prices from us.

Key Points:

- Low maintenance

- Impeccable performance

- High operational fluency

- Longer service life

Salient feature:

-

CGMP Model, Compact Model & Modular system.

-

Parts coming in contact with bottle / screw cap are made out of AISI 304, good housekeeping

-

Single motor synchronizes conveyor, star wheels and platform turret.

-

A Special safety clutch devices are being integrated on in feed & out feed Star wheel system for stoppage of machine in the event, vial is over turned.

-

A special background Suppression sensor stops machine automatically in the event, there is no screw cap in delivery chute.

-

Electro-pneumatic No Bottle – No Cap System.

-

Two Cam system which controls Cap pick up assembly and Cap release assembly

-

New innovative Magnetic hysteria sealing head for capping on bottle with incorporated clutch system.

-

Easy change over from Screw cap to ropp cap and vice versa.

-

Various cap feeding option available like vibrator feeder system, Mechanical cap feeder orientator or Water fall type elevator.

-

Fast format Changeover from one size of container to other size due to use of custom designed part.

-

Distinctively designed position system prevents from cap being jammed.

-

6 Digit precise counting arrangement helps to manage production process.

-

Outfitted with emergency button for safety concern.

-

All electrical & Brought out items are of CE certified.

Technical Specification:

|

Machine Name |

4 head Combi Capping machine |

6 head Combi Capping machine |

8 head Combi Capping machine |

|

Model |

NKSC-150P |

NKSC-250P |

NKSC-350P |

|

Direction |

Left to Right |

Left to Right |

Left to Right |

|

Production rate |

Up to 100 Bottle per minute for 50 ml bottle |

Up to 120 Bottle per minute for 50 ml bottle |

Up to 180 Bottle per minute for 50 ml bottle |

|

Electrical supply |

1 HP for Main Drive |

1 HP for Main Drive |

2 HP for Main Drive |

|

No of Screw Capping Head |

4 head |

6 Head |

8 Head |

|

No of ROPP Head |

4 Head |

4 head |

4 head |

|

Auto cap Pick Up ratio |

≥99.9% |

≥99.9% |

≥99.9% |

|

Qualified capping ratio |

≥99.8% |

≥99.8% |

≥99.8% |

|

Power requirement |

440 V ,3 Phase (4 Wire System ) 50 HZ |

440 V ,3 Phase (4 Wire System ) 50 HZ |

440 V ,3 Phase (4 Wire System ) 50 HZ |

|

Height of Conveyor |

Adjustable from 800 to 850 mm |

Adjustable from 800 to 850 mm |

Adjustable from 800 to 850 mm |

|

Bottle dia |

22 mm to 80 mm max |

22 mm to 80 mm max |

22 mm to 80 mm max |

|

Bottle height |

55 mm to 200 mm max |

55 mm to 200 mm max |

55 mm to 200 mm max |

|

Screw cap dia |

22 mm to 52 mm di cap |

22 mm to 52 mm dia cap |

22 mm to 52 mm dia cap |

|

ROPP Cap Dia |

20 mm to 40 mm |

20 mm to 40 mm |

20 mm to 40 mm |

|

Dimension (L X W X H) mm |

1530 x 812 x 1900 |

1830 x 812 x 1900 |

2130 X 915 x 1900 |

Add on Feature:

-

PLC - HMI Interface

-

Cap Feeder Elevator

-

Automatic Head Up and Down System

-

Toughened Glass or Acrylic Safety Cabinet for Machine.

Applicable industry:

-

Pharmaceuticals

-

Distilleries & Breweries

-

Cosmetics & Toiletries

-

Lube & Edible Oil

-

Pesticides

-

Food & Ancillaries

-

Mineral water

-

Pickle manufacturing

|

N K INDUSTRIES

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese